Professional knife sharpening (who and what you need to know)

I recently realized just how incredibly dull my kitchen knives had become. Not only were they not cutting like they used to, but I could visibly see that there was no real edge left. I knew that I could use my honing rod all I wanted, but that it wouldn’t get me that nice edge back. So, I started searching for a professional knife sharpening in Denver and Boulder.

I didn’t want to go to the mall or some big store. Instead, I was hoping to find someone out there that was passionate about knives and keeping them sharp. Someone that has an eye for blades like I do for how a bespoke suit should fit.

I ended up calling Jeff Yarrington of Shimmering Edge.

On a warm Tuesday afternoon, he picked up my sad looking knives and promised to sharpen them by the end of the week. Suffice it to say, Jeff overdelivered. When he returned my knives, I couldn’t believe how sharp they were. Suddenly, my knives were doing all the work again, just like they should be.

In the brief amount of time that he and I spoke in person, I realized that there is a lot more to knife sharpening than we all think. Consequently, I knew it would make for a great article.

So, I sat down with Jeff and asked him some questions about sharpening. I think you’ll see that he overdelivered again.

[Ryan] Jeff, what do you think is the number one mistake people make that contributes most to their kitchen knives dulling?

[Jeff] Actually, this is a more difficult question than it sounds – there are about 10 to 15 factors that make a knife go dull. So, I’m going to list my top 6 reasons. This is not a ranking because each person is different.

- Don’t cut on anything that is not a cutting board.

Decorative glass cutting boards are not cutting boards. They will dull your knife as soon as the knife makes contact.

Most plates are made of ceramics or glass or some other substance that is harder than your kitchen knives, don’t cut on them except with your steak knife (steak knives should be serrated).

If you ding your knife on your granite kitchen counter, you have likely dulled the contact spot.)

- When preparing food don’t use the edge of your knife to slide food, just cut food out of the way. Turn your knife over and slide the food with the back spine of your knife. I can tell if a person is left or right handed if my customer has this habit.

- Don’t use knives for anything except their intended purposes, especially paring knives. Paring knives are very thin knives and are not meant for impacting cutting boards. If you use a paring knife as your chef knife, it will dull quickly.

- The amount of use. It’s simple, the more you use your knife the faster it will dull.

- Not honing, also known as steeling your knife or honing/steeling improperly.

The type of steel and how hard that steel is made is a big factor on edge retention. Higher quality knives will usually have a longer edge retention.

I think it’s easy for most people to not realize how dull their blades have become until they are really dull. Is there any schedule you’d recommend for general maintenance sharpening?

You can see from my answer to question 1 that one schedule doesn’t fit everybody. The bottom line is when you hone or steel your knife correctly and your knife still won’t cut through your food easily, then it is time for a sharpening. I would say that for home use, many people’s knives will last between 6 months to a couple of years depending on the factors in question 1 and other factors that were not listed above.

Can you tell us a bit about your process? In other words, are all blades sharpened the same way? What is it that you do that I can’t do at home with my honing steel?

Honing steels are not sharpeners unless they are diamond impregnated or made of ceramic. So the steel that comes with sharpening blocks is made to realign the edge of your knife. Many manufacturers call them sharpeners, but they are not. So, as you use your knife the edge will get bent over to both sides of your blade and this is why a hone seems like it sharpens your knife at first but later doesn’t seem to be sharpening at all. Well, it was never sharpening in the first place.

My quick philosophy on sharpening knives:

I like mountable, repeatable precision. I do not like high-speed methods. Such as, high-speed grinders and high-speed band sanders for sharpening the edge of blades. They will get your knives sharp but can very easily remove more steel than is necessary and overheat and damage the temper of a knife, which weakens the knife. Usually, a good sharpener won’t let that happen. Hand methods are fine if you are highly proficient, but mountable repeatable systems are best in my opinion. With mountable repeatable slow speed systems, you can better control how much steel is removed and with the higher levels of precision. These methods do take a bit longer, but I’m more about quality than quantity.

Most of the knives are sharpened with my two main methods; the WickedEdge system or the Tormek, but there are exceptions even to these two methods.

For most knives, I use the Tormek slow wet grinding sharpening system. The wheel on this system only rotates at 90 rpm. I use two Tormek machines in my process. The first is used as the main sharper and is almost always set to 1000 grit which is a pretty fine starting grit. Starting at this level of refinement is slower, but gives me great control on the amount of steel being removed. Also, 1000 grit is the level of refinement that most knife manufacturers sell new knives at.

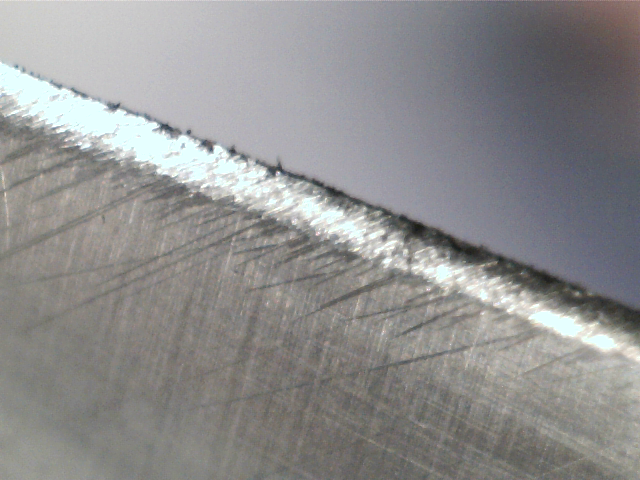

I can go as low as 220 grit for knives that are in really bad shape, but even the dullest of knives don’t usually require this course of a grit. I then use the second Tormek with a very fine grit Japanese Water stone. This stone polishes the edge to a mirror finish and leaves the knife razor sharp with a scratch pattern smaller than 3 microns. The last step of this method uses the leather honing wheel, but since the Japanese Water stone polishes the edge so well I only need to use a very light touch to remove whatever microscopic burr is left over from the polishing step.

The second sharpening method I use is the WickedEdge sharpening system. This is a mountable and repeatable hand method I use in conjunction with a digital angle gauge. I like to call the method the perfectionist method. I use this method for people who what the best sharpening that can be found anywhere. Since the degree of precision is at 1/20th of a degree on every pass of the sharpening stone, this method has the best control of steel removal possible. Also, with this system, I can refine a blade all the way down to 0.5 microns and smaller. Usually, only straight razors need to go to this level of refinement. As you might expect this method is slower so does cost more, but you can’t get any better than this method. If you are super particular of your knives this is the method for you.

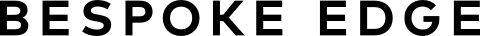

Before

After

What are you doing differently from the kitchen stores in the mall or anyone else that promises a sharp blade in no time at all?

If you are using someone that can sharpen a knife in a couple of minutes, they are using methods they know will get to new steel as quickly as possible and most likely are removing more steel than is necessary. This knife will be plenty sharp, but if you have an expensive knife and you want that knife to perform as much like it did when it was brand new then these fast methods are not what you want for your knife.

I have compared some of my competitor’s knife sharpenings using a digital microscope against my own and see that I bring the knives I sharpen to a higher level of refinement. What’s this mean to you? A more refined edge lasts longer and does less tearing to your food, which translates into food staying fresher longer.

You might ask, “Isn’t removing metal what we want when we sharpen”? Here is why you want to remove as little as is necessary.

Brand new knife is on the left. The middle knife has had a few sharpenings and the right one shows a few more. How many? Who knows? The point here is as your knife is sharpened more and more it moves up into a thicker and thicker part of the knife blade. I just chopped the tops of to make my point. You can see that your knife will never perform exactly as it did when you first purchased it. Without what is called “thinning a blade” it would become more like a cleaver than a chef knife. This is a phenomenon that we sense when our knife isn’t cutting the same as it did when we first purchased it. After a few sharpenings without thinning, it will never perform the same. Thinning will keep it close to its original performance, but not exact.

Wrap up

Are you wondering just how sharp your kitchen blades are right now? Or maybe the axe in the garage? Speaking from personal experience, if you can’t remember the last time you had them sharpened, I think you’ll be amazed at how sharp they could be if you were to give Jeff a call for his professional knife sharpening services.

Overall, I couldn’t be more impressed with Jeff’s work and his level of professionalism. There’s a lot of passion behind what he does. If you have questions about the sharpening process, believe me, he has answers!

You may contact Jeff via his website, Shimmering Edge, or via his email: sharpen

By the way, you might enjoy reading our interview with Boulder Lifestyle Magazine editor, Andy Manz.